| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : YIZGEAR

Place of Origin : CHINA

MOQ : 2 Sets

Payment Terms : L/C, T/T

Supply Ability : 50 Sets/Month

Delivery Time : 35 Days

Packaging Details : Plywood Crate

Direction : Left Hand

Profile One : Helical Gear

Pressure Agnle : 20°

Compatible Vehicle Type : Mining Equipment

Dimension : As sample or drawing

Accuracy : ISO 8 Grade

The girth gear is the larger component in a gear pair, typically functioning as the driven wheel. Its primary role is to reduce output rotational speed while simultaneously increasing output torque, thereby providing substantial power to the equipment.

The driven pinion drives the ring gear. According to the gear ratio (number of teeth on the ring gear divided by number of teeth on the pinion), the pinion must rotate multiple times before the ring gear completes a single revolution. This achieves a reduction in rotational speed and a multiplication of torque.

Large dimensions, substantial weight, and high inertia.

Primarily used in equipment requiring low-speed, heavy-duty power transmission:

| Parameter | Specification |

|---|---|

| Custom Made | Available |

| Gear Profile Type | Cylindrical Gears |

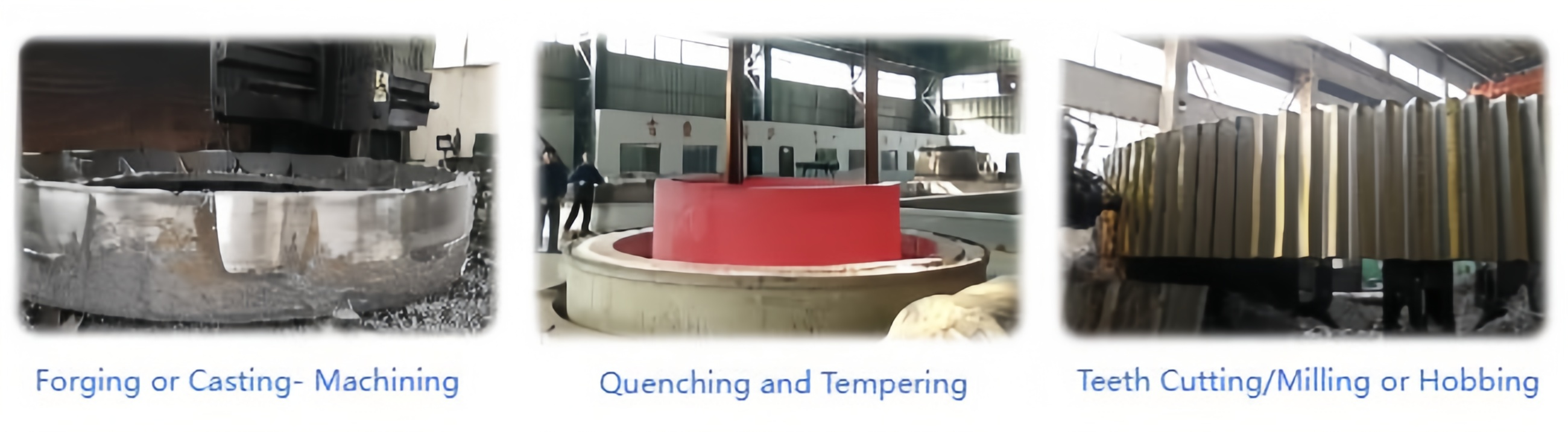

| Manufacturing Process | Gear Milling/Gear Hobbing |

| Teeth Grinding | Included |

| Module (M) | Custom |

| Number of Teeth (Z) | Custom |

| Pressure Angle (α) | Custom |

| Lead Angle | Custom |

| Accuracy Grade | ISO 8-9 Grade |

| Heat Treatment | Quenching and Tempering |

| Surface Hardness | 230-260 HB |

| CHINA/GB | ISO | ГΟСТ | ASTM | JIS | DIN |

|---|---|---|---|---|---|

| 45 | C45E4 | 45 | 1045 | S45C | CK45 |

| 40Cr | 41Cr4 | 40X | 5140 | SCr440 | 41Cr4 |

| 20CrMo | 18CrMo4 | 20ХМ | 4118 | SCM22 | 25CrMo4 |

| 42CrMo | 42CrMo4 | 38XM | 4140 | SCM440 | 42CrMo4 |

| 20CrMnTi | 18XГT | SMK22 | |||

| 20Cr2Ni4 | 20X2H4A | ||||

| 20CrNiMo | 20CrNiMo2 | 20XHM | 8720 | SNCM220 | 21NiCrMo2 |

| 40CrNiMoA | 40XH2MA/40XHMA | 4340 | SNCM439 | 40NiCrMo6/36NiCrMo4 | |

| 20CrNi2Mo | 20NiCrMo7 | 20XH2MA | 4320 | SNCM420 |

|

|

Transmission Gear Shaft Custom-Made with Gear Milling and Gear Hobbing Images |